Non-Rising Stem Gate Valves: Key Features and Benefits from a Leading Factory

2025-12-30

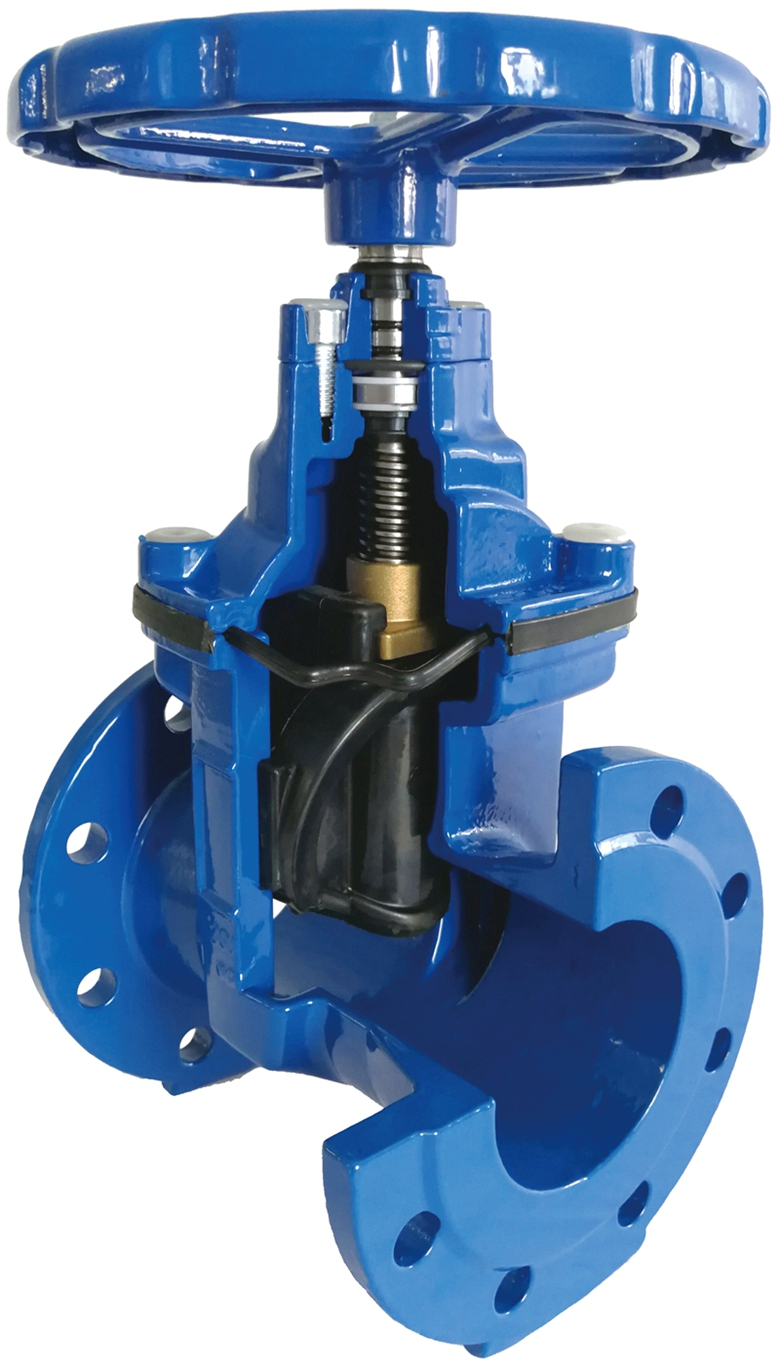

When it comes to industrial valves, precision and reliability are non-negotiable—especially in applications where flow control must be exact and maintenance minimal. Enter non-rising stem gate valves: an engineering marvel that offers unparalleled efficiency and durability. As specialists in valve manufacturing, DRIFCO has honed these designs to meet the toughest demands, delivering key features and benefits that set a new standard in the industry. In this blog, we'll dive deep into what makes these valves a standout choice, exploring their unique advantages and how they can optimize your operations. Ready to discover the cutting-edge solutions that keep systems running smoothly? Let's get started.

Essential Features of Our Non-Rising Stem Gate Valves

One standout aspect of our non-rising stem gate valves is how they conserve space in tight installations. Unlike traditional designs where the stem moves upward during operation, ours keeps the stem stationary while the gate threads internally, eliminating the need for overhead clearance. This makes them ideal for underground or confined applications in water treatment or industrial pipelines, where every inch counts.

We've enhanced durability by integrating robust materials like stainless steel stems and reinforced sealing components, which resist corrosion and wear over time. This leads to fewer maintenance calls and longer service life, even in harsh environments with high pressure or abrasive fluids. Users often report smoother operation and reduced leakage compared to standard models.

Another key feature is their user-friendly design, which simplifies installation and adjustments. With clear markings and accessible bonnets, technicians can quickly service valves without specialized tools, reducing downtime. This practical approach ensures reliability while keeping operational costs low, making our valves a smart choice for efficiency-focused projects.

Benefits That Set Our Gate Valve Line Apart

Crafted with exceptional durability, our gate valves feature forged carbon steel bodies that withstand extreme pressures and temperatures far beyond industry standards. Unlike typical valves that may falter under demanding conditions, each unit undergoes rigorous testing to ensure leak-proof performance for decades, reducing maintenance headaches and unexpected downtime.

What truly distinguishes our line is the innovative streamlined design, which minimizes flow resistance and enhances operational efficiency. We've integrated a self-lubricating stem system that prevents seizing and corrosion, a common pitfall in standard valves, ensuring smooth, effortless operation even after long periods of inactivity.

Beyond technical specs, we prioritize versatile compatibility, offering a wide range of sizes and end connections tailored to diverse applications from oil and gas to water treatment. This adaptability, combined with our commitment to rapid custom solutions, provides a tangible edge for industries seeking reliability without compromise.

Why Choose These Valves for Industrial Applications

Selecting the right valves for industrial applications isn't just about picking a component; it's about ensuring reliability, efficiency, and safety in demanding environments. These valves are specifically engineered to handle high pressures, corrosive fluids, and extreme temperatures, making them essential for industries like oil and gas, chemical processing, and power generation. Their robust designs help minimize downtime and maintenance costs, providing long-term value that goes beyond the initial investment.

One key reason to opt for these valves is their versatility in addressing diverse operational challenges. Unlike standard options, they offer customizable features such as precise flow control, leak-proof seals, and compatibility with various materials, which cater to specific needs without compromising performance. This adaptability ensures that whether you're managing fluid dynamics in a refinery or controlling steam in a plant, the valves deliver consistent results under fluctuating conditions.

Given the critical nature of industrial systems, safety is paramount, and these valves excel by incorporating advanced mechanisms that prevent failures and accidents. Innovations like automated shut-off capabilities and real-time monitoring interfaces enhance operational oversight, reducing human error and improving response times. By choosing these valves, industries not only boost productivity but also foster a safer workplace, aligning with modern standards for sustainability and risk management.

Manufacturing Excellence Behind Our Valves

When it comes to the heart of fluid control systems, the quality of a valve isn't just a feature—it's the foundation of reliability and performance. That's why every valve we produce undergoes meticulous attention to detail, from the initial design sketches to the final assembly. Our approach blends advanced engineering with time-tested craftsmanship, ensuring each component meets stringent standards for durability and precision. This isn't about mass production; it's about creating tools that stand up to the toughest industrial challenges, delivering seamless operation in critical applications where failure isn't an option.

What sets our valves apart is the relentless pursuit of innovation in our manufacturing processes. We've integrated cutting-edge technologies like 3D modeling and automated machining, which allow for tighter tolerances and enhanced consistency across batches. But we don't stop there—our team of skilled technicians brings a human touch to every stage, conducting rigorous quality checks and fine-tuning adjustments that machines alone can't replicate. This synergy of tech and talent results in valves that not only perform flawlessly but also adapt to evolving industry demands, offering custom solutions without compromising on core integrity.

Ultimately, the excellence behind our valves reflects a deeper commitment to sustainability and customer trust. By sourcing high-grade materials and optimizing production for minimal waste, we ensure longevity that reduces maintenance and environmental impact. Each valve tells a story of dedication, crafted to empower industries from energy to water management with dependable control. It's this unwavering focus on quality that turns a simple component into a cornerstone of operational success, backed by a legacy of precision you can rely on day in and day out.

Real-World Scenarios That Benefit from Non-Rising Stems

In bustling industrial settings, non-rising stem valves stand out for their compact design. Imagine a cramped chemical processing plant where every inch of space is precious—these valves fit snugly into tight piping configurations without the risk of a rising stem interfering with overhead equipment or adjacent structures. Their reliable operation in high-pressure environments means engineers can depend on them to shut off flows seamlessly, even when vibrations from nearby machinery would typically jostle other valve types.

Consider offshore oil rigs, where harsh conditions like saltwater corrosion and extreme temperatures challenge every component. Non-rising stems excel here by reducing exposure—the stem stays protected inside the valve body, minimizing wear from the elements. Maintenance teams appreciate how this design cuts down on frequent inspections, allowing for smoother operations in remote, hard-to-reach locations where replacing parts could involve costly downtime or logistical headaches.

Another practical use pops up in municipal water systems, where non-rising stem valves help manage underground pipelines with ease. Envision a dense urban area where valves are buried beneath streets—their compact, non-protruding stems prevent damage from shifting soils or incidental excavation work. This durability ensures consistent water flow control without the need for constant adjustments, making them a go-to choice for city planners prioritizing long-term reliability over flashy features.

How These Valves Improve Long-Term Performance

Valves engineered with advanced materials like stainless steel or ceramic coatings resist corrosion and wear, ensuring reliable operation for years. This durability reduces maintenance demands and extends service life in harsh environments, making them a cost-effective investment.

Precision designs minimize internal friction and turbulence, which not only boosts efficiency but also lessens stress on components. Such thoughtful engineering prevents common failures like leaks or blockages, contributing to consistent performance over time.

With features like self-cleaning mechanisms or modular parts, these valves adapt to varying conditions without degradation. This adaptability enhances their longevity and supports sustainable use, setting them apart in a competitive market.

FAQ

Non-Rising Stem Gate Valves are a type of valve where the stem does not rise when the valve is opened or closed, which is particularly useful in tight spaces or applications requiring minimal vertical movement. They control flow by raising or lowering a gate within the valve body, offering reliable shut-off capabilities, unlike rising stem valves that extend outward with operation.

These valves are prized for their compact design, durability in high-pressure environments, and resistance to corrosion and wear. Features often include a robust construction with materials like stainless steel or bronze, a non-rising mechanism that prevents stem damage, and ease of maintenance due to their simple internal structure.

Sourcing from a top-tier factory ensures superior quality control, custom engineering solutions, and adherence to international standards like API or ISO. Benefits include enhanced reliability, longer service life, and access to technical support, making them ideal for critical applications in oil, gas, or water treatment industries.

Yes, they excel in sectors like oil and gas, chemical processing, power generation, and water management, where space constraints and high-pressure conditions are common. Their leak-tight sealing and minimal maintenance needs make them a go-to choice for pipelines, refineries, and industrial plants.

Regular inspection of seals and stem threads, lubrication of moving parts, and checking for signs of corrosion or wear are key. Since the stem doesn't rise, it's less prone to external damage, but internal components should be cleaned periodically to prevent clogging or failure.

Absolutely. Leading factories often offer customization options such as specific material coatings, varying sizes from small to large diameters, and tailored pressure ratings. This allows them to handle extreme temperatures, abrasive fluids, or unique installation configurations effectively.

Challenges can include potential stem jamming if debris accumulates or difficulty in visual confirmation of valve position. Solutions involve using protective covers, installing position indicators, and ensuring proper installation with clean lines to minimize operational issues.

Conclusion

Non-rising stem gate valves offer essential features designed for industrial reliability. Our valves incorporate robust materials and precision engineering, ensuring tight sealing and resistance to wear. The non-rising stem design keeps the valve height constant, making them ideal for confined spaces while reducing installation challenges. This innovation enhances durability by minimizing external exposure to contaminants.

These valves provide distinct benefits that set them apart, including improved long-term performance through reduced maintenance needs. Manufacturing excellence underpins our product line, with rigorous quality control and advanced technology ensuring consistent operation. In real-world scenarios, such as in pipelines or processing plants, non-rising stems prevent stem damage and leakage, boosting efficiency. Choosing these valves for industrial applications means prioritizing safety, cost-effectiveness, and adaptability to harsh environments, supported by our leading factory's expertise in delivering reliable solutions.

Contact Us

Contact Person: George

Email: [email protected]

Tel/WhatsApp: 13863633883

Website: https://www.es-fire.com