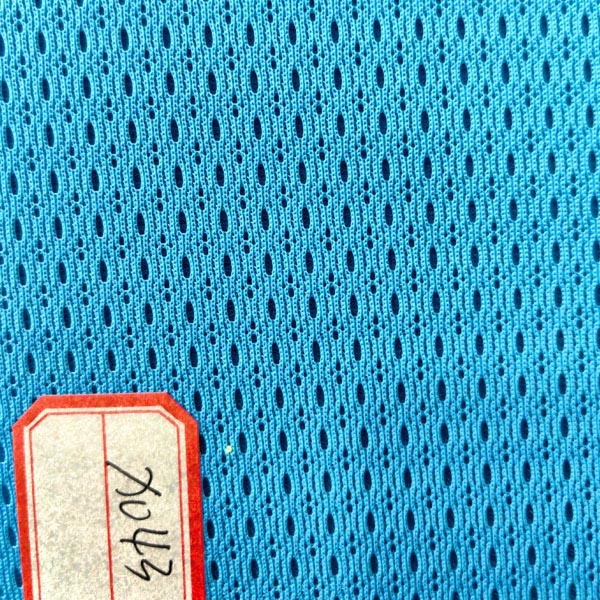

What is Sandwich Mesh Fabric?

2023-10-17

Sandwich mesh fabric, also known as spacer mesh fabric or 3D mesh fabric, is a type of textile used in various applications due to its unique construction and properties. It is commonly used in sportswear, shoes, bags, backpacks, medical products, and even car seats.

The structure of sandwich mesh fabric consists of three layers:

1. Outer Layer: This is typically made of a durable material like polyester or nylon, which provides strength and protection to the fabric.

2. Inner Layer: The inner layer is made of a softer, breathable material, often a blend of polyester and elastane, to provide comfort and moisture-wicking properties.

3. Spacer Layer: The key feature of sandwich mesh fabric is the spacer layer, which is located between the outer and inner layers. This layer is composed of monofilament or multi-filament yarns that create a three-dimensional structure with evenly distributed air pockets. These air pockets allow for better airflow and ventilation, making the fabric highly breathable and lightweight.

The benefits of sandwich mesh fabric include:

1. Breathability: The 3D structure with air pockets enhances ventilation, promoting airflow and reducing heat and moisture buildup. This feature is particularly valuable in sportswear and other active-wear applications.

2. Comfort: The soft inner layer of the fabric provides a pleasant feel against the skin, preventing chafing and discomfort during extended use.

3. Moisture Management: The breathable nature of the fabric allows moisture and sweat to escape quickly, keeping the wearer dry and comfortable.

4. Lightweight: Sandwich mesh fabric is lightweight, which is advantageous for reducing the overall weight of products such as shoes or bags.

5. Durable: The construction of sandwich mesh fabric, with the protective outer layer, contributes to its durability and resistance to wear and tear.