Advantages and Disadvantages of Beryllium Copper

2024-05-31

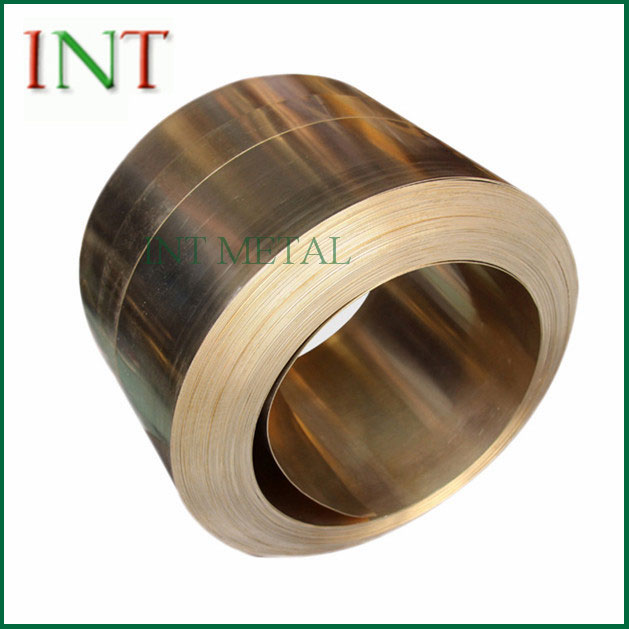

Beryllium copper (BeCu), also known as copper beryllium (CuBe), is a highly versatile and unique copper alloy known for its excellent combination of physical, mechanical, and electrical properties. It is widely used in various industries, including aerospace, automotive, electronics, and telecommunications. Here’s an in-depth look at beryllium copper:

Characteristics

1. Composition:

- Typically consists of 0.5% to 3% beryllium and the remainder copper.

- Sometimes includes other alloying elements like nickel or cobalt to enhance specific properties.

2. Physical Properties:

- High strength and hardness, comparable to high-grade alloy steels.

- Excellent thermal and electrical conductivity.

- Good corrosion resistance.

- Non-sparking and non-magnetic, making it safe for use in hazardous environments.

3. Mechanical Properties:

- High fatigue strength and resistance to stress relaxation.

- Excellent formability and machinability.

- Can be heat treated to increase strength and hardness.

Applications

1. Aerospace:

- Used in critical components like bearings, bushings, and landing gear parts due to its strength and wear resistance.

2. Electronics:

- Ideal for making electrical connectors, springs, and switches because of its high electrical conductivity and elasticity.

3. Automotive:

- Employed in components such as sensors, connectors, and various engine parts due to its durability and reliability.

4. Oil and Gas:

- Utilized in non-sparking tools and equipment to prevent ignition in explosive environments.

5. Telecommunications:

- Used in signal transmission devices, contacts, and switches for its excellent electrical properties.

Advantages

1. High Strength and Hardness:

- Beryllium copper alloys can achieve high levels of strength and hardness, making them suitable for demanding applications.

2. Thermal Stability:

- Maintains mechanical properties at elevated temperatures.

3. Electrical and Thermal Conductivity:

- Excellent conductivity, which is beneficial in electrical and electronic applications.

4. Non-Sparking:

- Safe for use in environments where sparks could cause explosions or fires.

5. Corrosion Resistance:

- Resists corrosion in various environments, including marine and industrial applications.

Disadvantages

1. Cost:

- Beryllium copper is relatively expensive compared to other copper alloys.

2. Health Risks:

- Beryllium is toxic, and inhalation of its dust or fumes can cause chronic beryllium disease (CBD) or berylliosis, a serious lung condition. Proper safety measures must be followed during machining and handling.

3. Limited Suppliers:

- The availability of beryllium copper may be limited due to the specialized nature of its production.

Safety Considerations

1. Handling:

- Use appropriate protective equipment such as gloves and masks when handling beryllium copper to prevent exposure to dust or fumes.

2. Machining:

- Ensure proper ventilation and dust collection systems are in place when machining to capture any airborne particles.

3. Regulations:

- Comply with local and international regulations regarding the use and disposal of beryllium-containing materials.

Heat Treatment

1. Solution Annealing:

- Involves heating the alloy to a high temperature and then rapidly cooling it to achieve a soft and ductile state.

2. Age Hardening (Precipitation Hardening):

- The alloy is reheated to a lower temperature and held there for a specified period, which causes the formation of beryllium-rich precipitates, increasing strength and hardness.

Conclusion

Beryllium copper is a high-performance alloy known for its exceptional strength, conductivity, and durability. It plays a crucial role in various high-stress, high-performance applications across multiple industries. Despite its cost and the need for careful handling due to health risks, its unique properties make it indispensable for many advanced engineering solutions. Proper safety measures and adherence to regulations are essential when working with beryllium copper to ensure safe and effective use.