Features of Flake Blade Plastic Crusher

2024-06-19

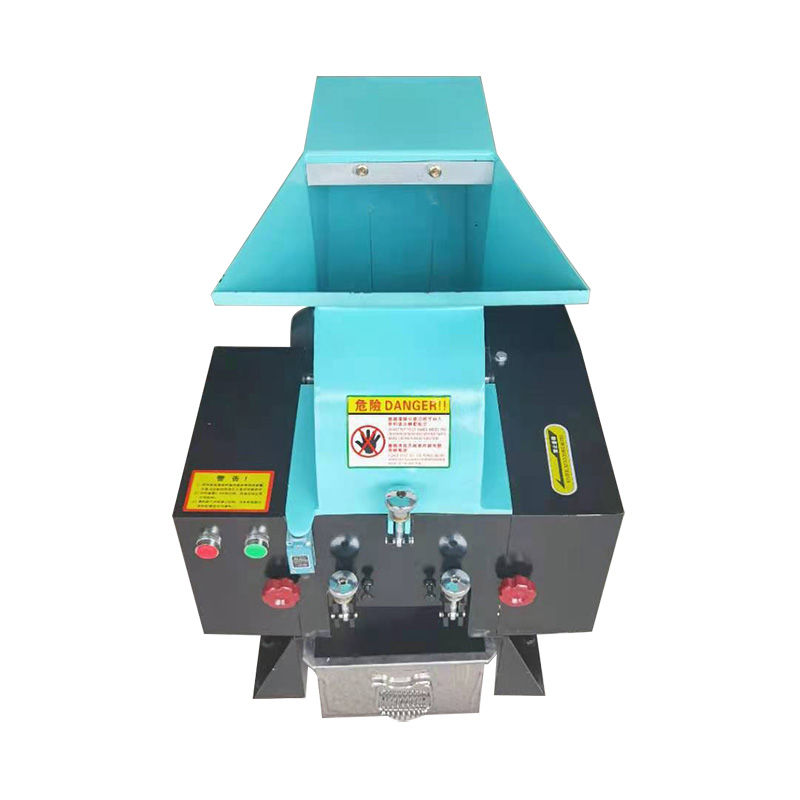

A flake blade plastic crusher is a specialized machine used for size reduction of plastic flakes or granules into smaller pieces, typically for recycling or reprocessing. This type of plastic crusher is designed to handle plastic materials that are larger in size and rigid in nature, such as plastic bottles, containers, crates, and other plastic products. Here’s an overview of the features, workings, and applications of a flake blade plastic crusher:

Features of Flake Blade Plastic Crusher:

1. Crushing Mechanism:

- Blades: Equipped with sharp, rotating blades designed to cut and shred plastic materials into smaller flakes or particles.

- Blade Configuration: Typically includes multiple blades arranged on a rotating shaft to efficiently break down plastic materials.

2. Material Handling:

- Feed Hopper: Where plastic materials are loaded into the crusher for processing.

- Conveyor System: Transports plastic flakes or granules into the crushing chamber for continuous operation.

3. Size Reduction:

- Output Size: Generates plastic flakes or granules of controlled size depending on the screen or sieve used.

- Adjustable Settings: Some crushers allow adjustment of blade clearance and rotor speed to achieve desired particle size.

4. Construction:

- Heavy-Duty Design: Constructed from durable materials such as steel to withstand the impact and stress of crushing operations.

- Safety Features: Includes safety guards and emergency stop mechanisms to ensure safe operation.

5. Motor and Drive System:

- Power: Operates with a motor of sufficient power to drive the rotating blades and handle the crushing load.

- Drive System: Typically uses a belt or direct drive system for efficient power transmission.

6. Control Panel:

- User Interface: Provides controls for starting, stopping, and adjusting operational parameters of the crusher.

- Safety Controls: Includes overload protection and other safety features to prevent equipment damage and ensure operator safety.

Working Principle:

- Plastic materials are fed into the crusher through the feed hopper.

- The rotating blades, often arranged in a V-shaped configuration, cut and shred the plastic into smaller pieces as they pass through the crushing chamber.

- The crushed plastic flakes or granules are then discharged through a screen or sieve of a specific size to control the final particle size.

- Continuous operation allows for efficient processing of plastic materials into reusable forms suitable for recycling or further processing.

Applications:

1. Plastic Recycling Plants:

- Used to crush and size-reduce plastic waste materials into smaller flakes or granules for recycling.

- Prepares plastic materials for subsequent processes such as extrusion, pelletizing, or injection molding.

2. Manufacturing Facilities:

- Enables reprocessing of scrap or rejected plastic products into reusable materials for manufacturing new products.

- Reduces waste and optimizes material usage in production processes.

3. Waste Management:

- Supports waste reduction efforts by processing plastic waste into recyclable forms, contributing to environmental sustainability.

4. Plastic Industry:

- Used in industries producing plastic products to manage production waste and surplus materials effectively.

Considerations:

- Material Compatibility: Ensure the crusher is suitable for the type and size of plastic materials being processed.

- Throughput: Evaluate the crusher’s capacity to handle the required volume of plastic materials per hour.

- Maintenance: Regular maintenance and cleaning are essential to ensure the crusher operates efficiently and prolongs its lifespan.

Conclusion:

A flake blade plastic crusher plays a crucial role in the recycling and reprocessing of plastic materials by reducing larger plastic items into smaller flakes or granules. It supports various industries and facilities in managing plastic waste effectively while contributing to sustainable practices. Understanding its features, working principles, and applications helps in selecting and utilizing a flake blade plastic crusher to meet specific recycling and processing needs efficiently.