Functions and Features of Lighting PCB

2024-05-10

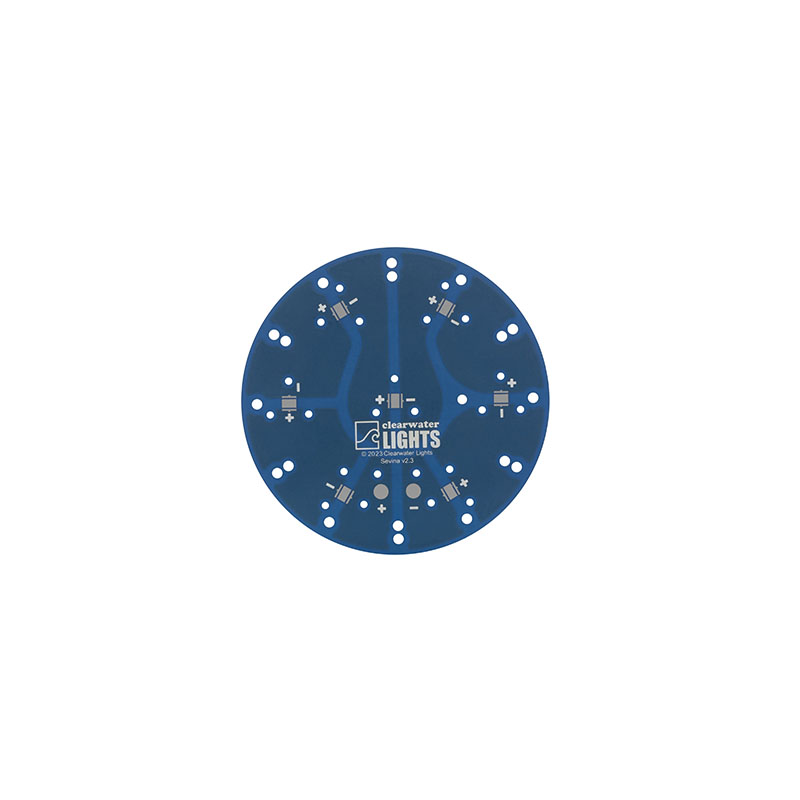

A lighting PCB (Printed Circuit Board) refers to a specialized circuit board used in lighting fixtures, lamps, or other lighting devices to control and distribute electrical power to the various components of the lighting system. Lighting PCBs are integral to the functionality and performance of modern lighting systems, offering several key functions and features:

1. Power distribution: Lighting PCBs serve as the central hub for distributing electrical power to the various components of the lighting system, including LEDs (Light-Emitting Diodes), drivers, sensors, and other electronic components.

2. Component mounting: Lighting PCBs provide a platform for mounting and interconnecting the electronic components of the lighting system, such as LEDs, resistors, capacitors, transistors, and integrated circuits (ICs). Components are soldered onto the PCB's surface or inserted into pre-drilled holes, depending on the specific design requirements.

3. Circuit layout: The layout of the PCB's circuitry is carefully designed to optimize the performance, efficiency, and reliability of the lighting system. This includes the placement and routing of traces, vias, and pads to minimize signal interference, reduce power losses, and ensure proper thermal management.

4. Control and regulation: Lighting PCBs may incorporate circuitry for controlling and regulating various aspects of the lighting system, such as brightness, color temperature, dimming, and color mixing. This may involve the integration of microcontrollers, sensors, and feedback mechanisms to achieve desired lighting effects and functionality.

5. Protection features: Lighting PCBs often include protective features to safeguard the components and ensure safe operation of the lighting system. This may include overcurrent protection, overvoltage protection, reverse polarity protection, and thermal protection mechanisms to prevent damage to the PCB and connected components.

6. Connectivity options: Lighting PCBs may offer various connectivity options for interfacing with external devices or systems, such as wireless communication modules (e.g., Bluetooth, Wi-Fi), wired interfaces (e.g., USB, Ethernet), or control protocols (e.g., DMX, DALI) for integration into larger lighting networks or automation systems.

7. Customization and scalability: Lighting PCBs can be customized and scaled to meet the specific requirements of different lighting applications, including architectural lighting, automotive lighting, stage lighting, and general illumination. Manufacturers can tailor the PCB design, layout, and functionality to optimize performance, efficiency, and cost-effectiveness for a wide range of lighting projects.

Overall, lighting PCBs play a critical role in the design, functionality, and performance of modern lighting systems, providing a flexible and reliable platform for controlling and distributing electrical power to illuminate spaces, enhance aesthetics, and create immersive lighting experiences.