Here are some key features and aspects of a metal sheet shearing machine

2023-12-26

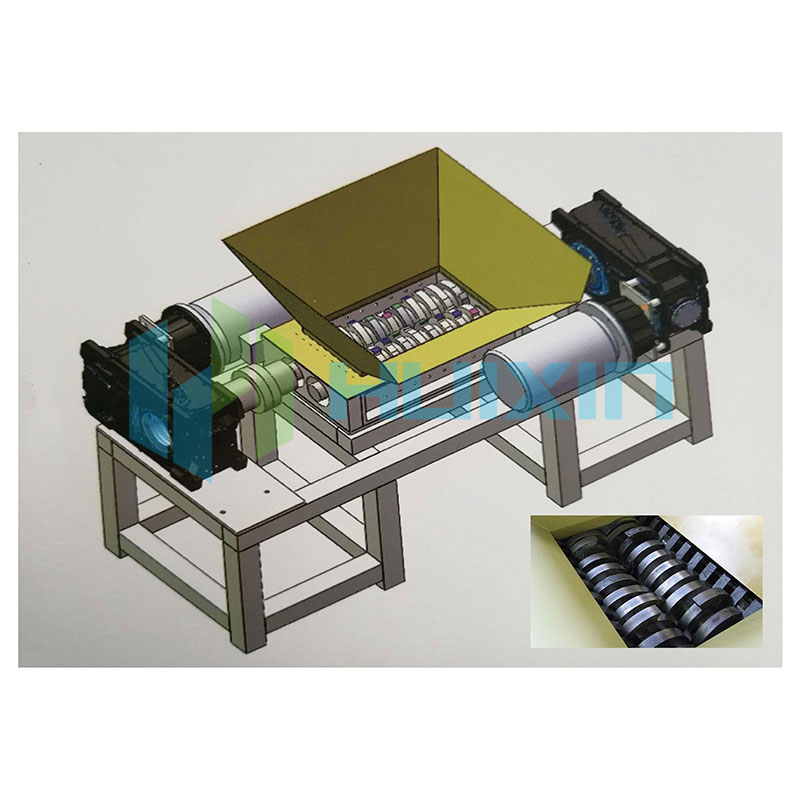

A metal sheet shearing machine is a mechanical device used for cutting or shearing metal sheets into desired shapes or sizes. These machines are commonly found in metal fabrication shops, manufacturing plants, and industries that work with sheet metal. The primary function of a shearing machine is to cut straight lines on metal sheets, and it's an essential tool for various metalworking processes.

Here are some key features and aspects of a metal sheet shearing machine:

1. Operation:

- Shearing Process: The shearing machine uses a blade, often a fixed upper blade and a moving lower blade, to apply force and cut through the metal sheet. The sheet is positioned between the blades, and the shearing action produces a straight-line cut.

2. Types of Shearing Machines:

- Mechanical Shears: Operate using mechanical components like gears and flywheels.

- Hydraulic Shears: Use hydraulic systems for enhanced power and precision.

- CNC Shearing Machines: Computer Numerical Control (CNC) technology allows for automated and programmable shearing processes.

3. Blades:

- Blade Material: Blades are typically made of high-quality tool steel or other durable materials to withstand the cutting forces and maintain sharpness.

4. Capacity:

- Shearing Capacity: The machine's capacity is determined by factors such as the maximum thickness and width of the metal sheet it can effectively shear.

5. Back Gauge:

- Back Gauge System: Many shearing machines have a back gauge system that helps position the metal sheet accurately before the shearing process. This aids in achieving precise cuts.

6. Safety Features:

- Safety Guards: Shearing machines are equipped with safety features such as guards to protect operators from moving parts during operation.

7. Cutting Length:

- Cutting Length Adjustment: Some machines allow for the adjustment of the cutting length, providing flexibility for different project requirements.

8. Speed Control:

- Adjustable Speed: Adjustable cutting speeds allow operators to control the pace of the shearing process based on the type and thickness of the material being cut.

9. Foot Pedal or Control Panel:

- Operation Controls: Shearing machines may have controls such as a foot pedal or a control panel for convenient and hands-free operation.

10. Versatility:

- Ability to Cut Various Metals: Shearing machines are designed to cut various types of metals, including steel, aluminum, and stainless steel.

11. Maintenance:

- Ease of Maintenance: Regular maintenance is essential for optimal performance. Machines with easily accessible components and user-friendly maintenance features are advantageous.

12. Accuracy:

- Precision Cutting: Modern shearing machines, especially those with CNC capabilities, offer high precision and accuracy in cutting, reducing material waste.

Metal sheet shearing machines are crucial for producing accurately cut metal pieces for fabrication, construction, and various industrial applications. When using these machines, operators must follow safety guidelines and adhere to proper maintenance practices to ensure efficient and safe operation.