Key considerations related to pipe clamp forgings

2024-03-07

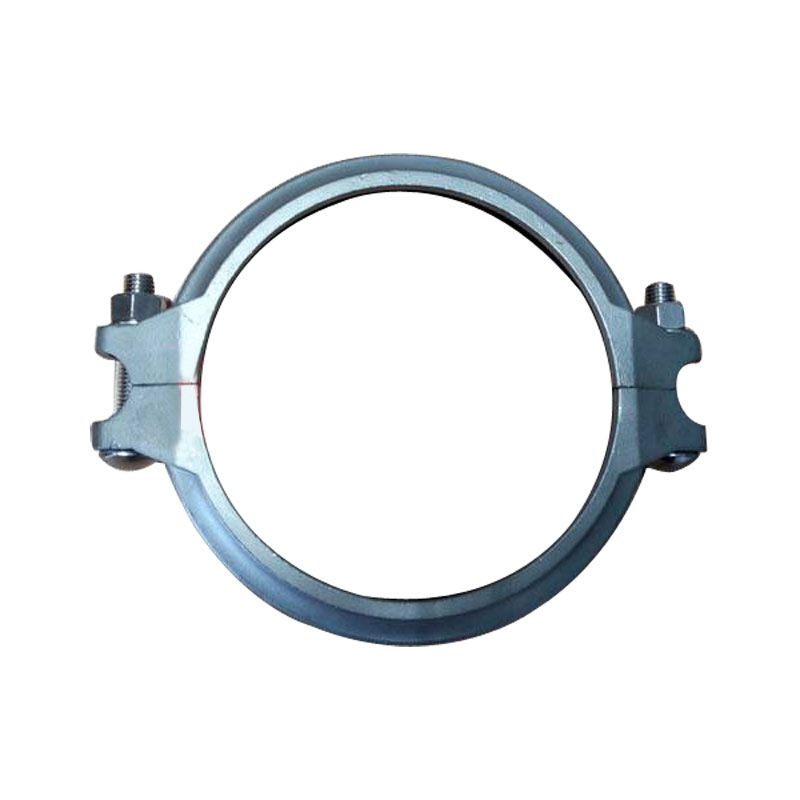

Pipe clamp forgings involve the process of manufacturing components used to secure and support pipes in various industrial applications. These clamps are essential for maintaining the stability and integrity of piping systems in areas such as construction, oil and gas, manufacturing, and infrastructure projects. Forgings are often preferred for pipe clamps due to their strength, durability, and resistance to deformation under heavy loads. Here are key considerations related to pipe clamp forgings:

1. Forging Process:

- Closed Die Forging: Closed die forging, or impression die forging, is commonly used for producing pipe clamp forgings. In this process, metal is shaped within dies that have a pre-designed cavity for the pipe clamp. This allows for precise control over the shape and dimensions of the clamp.

2. Material Selection:

- Materials for pipe clamp forgings are typically chosen for their strength, corrosion resistance, and durability. Common materials include carbon steel, alloy steel, and stainless steel. The selection depends on the specific application, environmental conditions, and load requirements.

3. Design Considerations:

- The design of pipe clamp forgings takes into account factors such as the size and type of pipes to be supported, the operating conditions (temperature, pressure), and the expected loads on the clamp. The design may include features such as threaded holes, grooves, or other mechanisms to facilitate installation and adjustment.

4. Heat Treatment:

- After the forging process, pipe clamp forgings may undergo heat treatment to enhance their mechanical properties. Heat treatment methods such as quenching and tempering are used to achieve the desired hardness, toughness, and strength.

5. Machining and Finishing:

- Following forging and heat treatment, pipe clamp forgings may undergo machining operations to achieve precise dimensions and ensure a smooth surface finish. Machining processes may include drilling, milling, or threading to prepare the clamp for installation.

6. Coating and Corrosion Protection:

- Depending on the material and application, pipe clamps may be coated or treated with corrosion-resistant finishes to protect them from environmental elements and extend their service life.

7. Testing and Quality Control:

- Rigorous testing and quality control measures are implemented during the manufacturing process to ensure that the pipe clamp forgings meet industry standards and specifications. This may include non-destructive testing, dimensional inspections, and material property testing.

Pipe clamp forgings play a critical role in providing structural support and stability to piping systems. The choice of forging processes, materials, and manufacturing methods depends on the specific requirements of the application and industry standards.