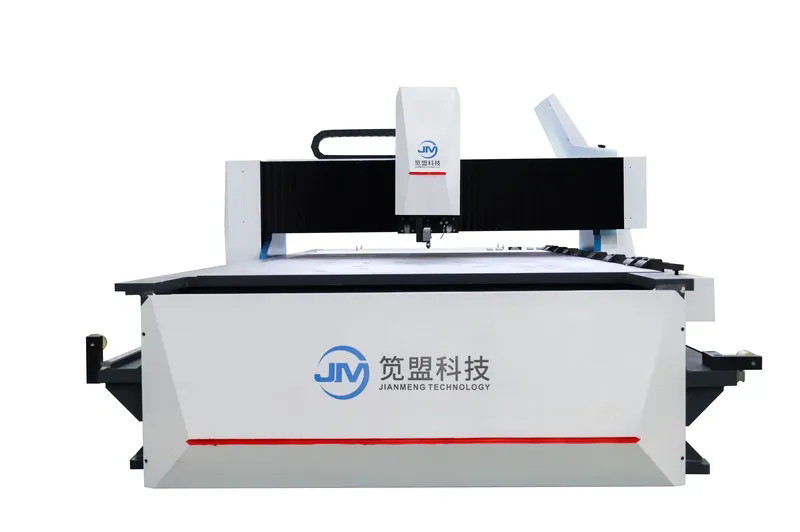

Precision and Efficiency with the Four-Side CNC V Grooving Machine

2024-09-03

In the realm of modern manufacturing, precision and efficiency are paramount. The Four-Side CNC V Grooving Machine stands out as an advanced tool designed to meet these demands with exceptional accuracy and versatility. This blog delves into the features, benefits, and applications of this innovative machine, illustrating why it’s a valuable addition to any manufacturing setup.

What Is a Four-Side CNC V Grooving Machine?

A Four-Side CNC V Grooving Machine is a sophisticated piece of equipment used primarily in the processing of sheet materials, such as metal, plastic, and composite panels. Unlike traditional grooving machines that may only work on one side or use manual adjustments, this CNC (Computer Numerical Control) machine is designed to efficiently groove all four sides of a workpiece simultaneously. The “V” in its name refers to the V-shaped groove it creates, which is essential for various applications in manufacturing and fabrication.

Key Features of the Four-Side CNC V Grooving Machine

1. Four-Side Grooving Capability

The primary feature of this machine is its ability to groove all four sides of a sheet material in one operation. This feature enhances productivity by reducing the number of setups and operations required. It is especially useful for processing large quantities of panels or materials that need consistent grooves on all sides.

2. CNC Control System

The CNC control system is the brain of the machine, providing precise control over the grooving process. Operators can program intricate grooving patterns, adjust cutting depths, and control feed rates with high accuracy. This level of control ensures that each groove is cut to exact specifications, resulting in consistent and high-quality results.

3. Versatile Material Processing

The Four-Side CNC V Grooving Machine is designed to handle a variety of materials, including metals, plastics, and composite materials. This versatility makes it an essential tool for industries that work with different types of sheet materials, such as aerospace, automotive, construction, and electronics.

4. High-Speed Operation

Equipped with advanced motors and drive systems, the machine can perform high-speed grooving operations without compromising precision. This speed enhances productivity and reduces processing time, making it suitable for high-volume manufacturing environments.

5. Automated Material Handling

Many Four-Side CNC V Grooving Machines come with automated material handling systems, such as conveyors or robotic arms, which streamline the loading and unloading of materials. This automation reduces manual labor and ensures a smooth workflow, improving overall efficiency.

6. Precision and Accuracy

The machine’s precise control mechanisms and advanced tooling ensure that each groove is cut with exceptional accuracy. This precision is crucial for applications requiring exact dimensions and tight tolerances, such as in the production of electronic enclosures or architectural panels.

Benefits of Using a Four-Side CNC V Grooving Machine

1. Increased Productivity

By allowing for simultaneous grooving of all four sides, this machine significantly reduces the time and effort required for material processing. This boost in productivity is particularly advantageous in industries where large quantities of materials need to be processed quickly and efficiently.

2. Consistent Quality

The CNC control system ensures that each groove is cut to exact specifications, resulting in uniform quality across all workpieces. This consistency is essential for maintaining high standards and meeting customer expectations.

3. Reduced Labor Costs

Automated features, such as material handling and precise programming, reduce the need for manual intervention and supervision. This automation translates to lower labor costs and allows operators to focus on other critical tasks.

4. Flexibility in Design

The ability to program various grooving patterns and depths provides flexibility in design and customization. Whether you need simple straight grooves or complex patterns, the machine can accommodate a wide range of design requirements.

5. Enhanced Safety

Modern CNC machines are equipped with safety features such as protective enclosures, emergency stop buttons, and advanced monitoring systems. These features help ensure a safe working environment and reduce the risk of accidents.

Applications of the Four-Side CNC V Grooving Machine

1. Metal Fabrication

In the metal fabrication industry, the Four-Side CNC V Grooving Machine is used to create grooves in sheet metal panels for applications such as enclosures, frames, and brackets. The precise grooving ensures proper fit and alignment of metal components.

2. Plastic and Composite Panels

The machine is also used to groove plastic and composite panels, which are commonly used in industries such as automotive and aerospace. Grooving these materials can improve their structural integrity and facilitate assembly processes.

3. Architectural Panels

For architectural applications, the machine can groove panels used in building facades, interior partitions, and decorative elements. The ability to create consistent grooves enhances the aesthetic appeal and functionality of architectural designs.

4. Electronics Enclosures

In the electronics industry, the Four-Side CNC V Grooving Machine is used to process enclosures and housings for electronic components. Precise grooving ensures that these enclosures fit together accurately and provide adequate protection for sensitive electronic parts.

5. Custom Fabrication

The versatility of the machine makes it suitable for custom fabrication projects, where specific grooving patterns and dimensions are required. This flexibility allows manufacturers to meet unique design specifications and produce custom components with ease.

Conclusion

The Four-Side CNC V Grooving Machine is a powerful tool that combines precision, efficiency, and versatility to meet the demands of modern manufacturing. Its ability to groove all four sides of a workpiece simultaneously, coupled with advanced CNC control, makes it an invaluable asset in various industries. By enhancing productivity, ensuring consistent quality, and offering flexibility in design, this machine helps manufacturers stay competitive and achieve high standards in their production processes.