Waterjet Parts: Ruby Orifice - A Comprehensive Q&A Guide

2024-10-23

In the world of waterjet cutting, the ruby orifice plays a crucial role in determining the efficiency and precision of the cutting process. This blog will address common questions about ruby orifices, their functionality, and their significance in waterjet systems.

What is a Ruby Orifice?

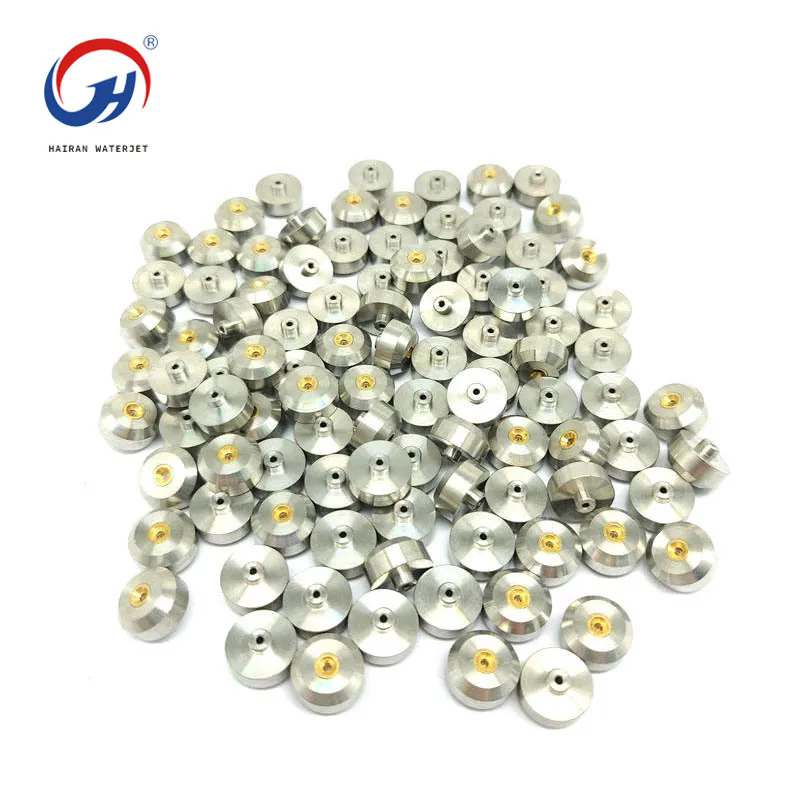

A ruby orifice is a component used in waterjet cutting systems that controls the flow of water through the nozzle. Made from synthetic ruby, this small yet vital part creates a focused high-pressure water stream that can cut through various materials, including metals, glass, and ceramics.

Why is Ruby Used for Orifices?

Ruby is used for orifices due to its exceptional hardness, which allows it to withstand the intense pressures and abrasives encountered during waterjet cutting. The hardness of ruby prevents wear and extends the life of the orifice, ensuring consistent performance over time. Additionally, ruby has excellent optical clarity, which can aid in certain cutting processes.

How Does a Ruby Orifice Work?

The ruby orifice functions by converting high-pressure water into a focused jet. Water is pumped at high pressure through the orifice, where it exits through a precisely sized opening. This narrow jet of water can reach velocities of up to 900 feet per second, enabling it to cut through tough materials with precision. The shape and size of the orifice are critical in determining the characteristics of the waterjet, including its cutting speed and accuracy.

What Are the Advantages of Using Ruby Orifices?

Ruby orifices offer several advantages:

Durability: Their hardness means they resist wear better than orifices made from softer materials, resulting in longer service life.

Precision: Ruby orifices provide consistent water flow, which contributes to precise cutting results.

Heat Resistance: Ruby can withstand high temperatures, making it suitable for the demanding conditions of waterjet cutting.

Corrosion Resistance: Ruby's chemical stability ensures that it remains unaffected by the materials it cuts, contributing to overall system reliability.

How Do Ruby Orifices Compare to Other Materials?

Ruby orifices are often compared to orifices made from materials like sapphire or carbide. While sapphire is also hard and resistant to wear, it is typically more expensive than ruby. Carbide, on the other hand, is less expensive but may wear out faster in abrasive cutting applications. Ruby's balance of durability, performance, and cost-effectiveness makes it a popular choice in many waterjet systems.

What Factors Should Be Considered When Selecting a Ruby Orifice?

When choosing a ruby orifice, consider the following factors:

Orifice Size: The diameter of the orifice affects the cutting speed and quality. Smaller orifices create finer cuts, while larger ones are better for thicker materials.

Pressure Ratings: Ensure that the orifice can handle the pressure levels of your specific waterjet system.

Compatibility: Confirm that the orifice is compatible with your waterjet cutting machine and any accessories you may be using.

Application Requirements: Different materials and thicknesses may require specific orifice sizes or types.

How Do You Maintain Ruby Orifices?

To ensure the longevity and performance of ruby orifices, follow these maintenance tips:

Regular Inspection: Check the orifice for wear or damage regularly, especially after extended use.

Clean the Nozzle: Keep the nozzle area free from debris or buildup that could affect water flow.

Monitor Pressure Levels: Ensure that the water pressure is within recommended limits to avoid premature wear.

Replace as Needed: If you notice a decrease in cutting performance or visible wear, replace the ruby orifice promptly to maintain cutting efficiency.

What Are Common Applications for Ruby Orifices?

Ruby orifices are used in various applications, including:

Industrial Cutting: In manufacturing, they are essential for cutting metals, plastics, and composite materials.

Art and Design: Artists and designers utilize waterjet cutting for intricate patterns in materials like glass and stone.

Aerospace and Automotive: Ruby orifices help create precise components and parts that meet strict specifications.

Construction: Used for cutting materials such as concrete and brick, they are vital in construction applications.

What Are the Limitations of Ruby Orifices?

While ruby orifices have many advantages, there are some limitations to consider:

Cost: Ruby orifices can be more expensive than those made from other materials, which may impact budget constraints.

Brittleness: Although they are hard, ruby can be brittle and may crack if subjected to excessive force or improper handling.

Compatibility: Not all waterjet systems are designed to accommodate ruby orifices, so it's important to ensure compatibility before purchase.

What is the Future of Ruby Orifices in Waterjet Technology?

The future of ruby orifices in waterjet technology looks promising. As cutting technologies advance, there is ongoing research into optimizing orifice design for enhanced performance. Innovations may lead to improved manufacturing techniques for ruby orifices, potentially reducing costs while maintaining their excellent properties. Furthermore, as industries continue to seek more efficient and precise cutting methods, the demand for high-quality ruby orifices is likely to grow.

Conclusion

Ruby orifices are critical components in waterjet cutting systems, providing durability, precision, and reliability. Understanding their features, benefits, and maintenance requirements can help users maximize the performance of their waterjet machines. As technology continues to evolve, ruby orifices will remain integral to achieving high-quality cutting results across various applications.