Why Are MLCC Machines Revolutionizing the Electronics Industry?

2025-04-27

In the world of electronics, small components often make the biggest impact. One such component is the Multi-Layer Ceramic Capacitor (MLCC), a crucial part used in a wide array of electronic devices, from smartphones to electric vehicles. But how are MLCC machines driving innovation in this space, and what role do they play in the production of these essential parts?

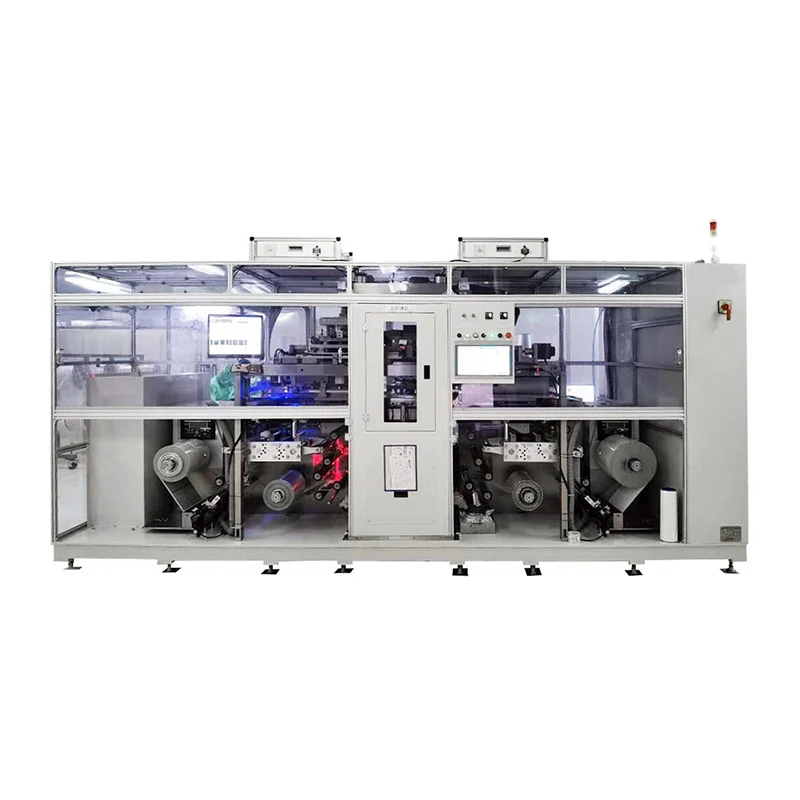

MLCC machines are specialized tools designed to manufacture capacitors with multiple layers of ceramic material, which are used for energy storage and filtering in electronic circuits. These machines are central to the high-precision, high-volume production required for today’s advanced electronics. By enabling the mass production of MLCCs with precise layers and tight tolerances, MLCC machines ensure that manufacturers can produce these vital components at scale, with consistency and efficiency.

The process behind MLCC production is complex, involving multiple steps, including layering, sintering, and cutting. MLCC machines automate much of this process, ensuring each step is performed to exact specifications. This automation not only speeds up production but also minimizes human error, resulting in higher-quality products with fewer defects. The precision involved in creating these tiny capacitors is critical, as even slight variations can affect the performance of the final electronic device.

The role of MLCC machines goes beyond merely speeding up production; they also allow for the development of more advanced and powerful MLCCs. With the growing demand for smaller, more efficient components in consumer electronics and electric vehicles, manufacturers are constantly looking for ways to fit more functionality into smaller spaces. MLCC machines enable the production of capacitors with more layers, higher capacitance, and improved performance characteristics, meeting the ever-increasing demands of modern electronics.

One of the standout features of MLCC machines is their ability to handle a variety of materials and designs. Different types of ceramics, electrodes, and coatings can be used in the manufacturing process, giving engineers and designers the flexibility to tailor capacitors for specific applications. Whether it's for high-frequency circuits, automotive systems, or medical devices, MLCC machines help create capacitors that perform optimally under a wide range of conditions.

As the demand for MLCCs continues to grow, especially with the rise of Internet of Things (IoT) devices, electric vehicles, and renewable energy systems, the role of MLCC machines will become even more important. These machines are helping to meet the need for high-performance components in a fast-evolving technological landscape. Their ability to produce capacitors with unparalleled precision and efficiency is allowing manufacturers to stay ahead in a competitive market.

MLCC machines are quietly driving the electronics revolution, enabling the production of components that power some of the most innovative technologies in the world. With their ability to produce high-quality, high-performance MLCCs in large quantities, these machines are becoming more indispensable as industries push for smaller, more efficient devices. The future of electronics may be small in size, but it’s big in potential, and MLCC machines are at the heart of that transformation.