Why Is the Pulp Pump Essential in the Paper Industry?

2025-01-07

In the paper manufacturing industry, one of the critical components that ensure smooth production is the pulp pump. Pulp pumps are used to transport slurry-like mixtures of wood fibers, water, chemicals, and other materials that make up the pulp used in paper production. Given the vital role they play in maintaining the efficiency of the process, you may be wondering, why is the pulp pump so essential in the paper industry? In this blog, we’ll take a closer look at the importance of pulp pumps, how they work, and why they are indispensable in paper mills.

What is a Pulp Pump?

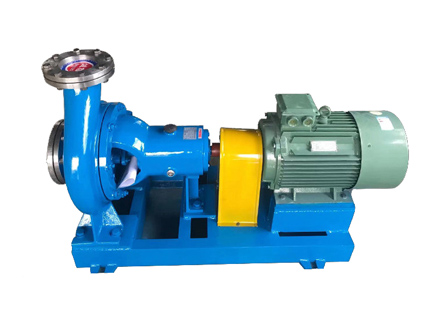

A pulp pump is a type of pump specifically designed to handle the thick, viscous, and sometimes abrasive slurry found in the paper-making process. Unlike standard pumps that are used for liquids, pulp pumps are engineered to handle the unique characteristics of pulp, which can contain large solid particles, fibers, and a high viscosity. These pumps are designed to move the pulp through different stages of the paper production line, ensuring that materials are transported efficiently and without interruption.

How Does a Pulp Pump Work?

The pulp pump works by using various mechanical actions to move pulp slurry from one location to another within a paper mill. These pumps typically operate using a centrifugal force, where the pump’s impeller creates a flow of pulp from the inlet and forces it out of the outlet. Depending on the type of pump, additional components like rotors or pistons might be used to increase the pressure and improve the flow of the pulp.

Pulp pumps are usually designed with materials that can resist wear and tear caused by the abrasive nature of the pulp. They are often made from durable alloys or rubber-lined materials to prevent damage and ensure longevity. The pumps are also equipped with seals and other mechanisms to prevent leakage and maintain efficiency.

Why Are Pulp Pumps Important?

1. Efficient Transport of Pulp Slurry:

Pulp slurry needs to be transported between different stages of the paper-making process, such as from the pulper to the cleaning and refining stages. A pulp pump ensures that this material is moved smoothly and efficiently, preventing blockages or delays in the production line. Without an effective pulp pump system, the production process could slow down significantly, leading to lower output and increased downtime.

2. Maintaining Consistent Flow:

Consistency is key in paper manufacturing. The pulp pump ensures that the flow rate of the pulp remains steady, which is essential for maintaining the quality of the final paper product. Variations in flow can lead to inconsistencies in pulp density, which can affect the strength, texture, and appearance of the paper being produced.

3. Handling Thick and Abrasive Materials:

The pulp in paper mills is typically a mixture of wood fibers, chemicals, and water, which is much thicker and more abrasive than water or other liquids. Regular pumps may not be able to handle such materials without becoming clogged or worn down. Pulp pumps are specifically designed with these challenges in mind, ensuring that they can handle high viscosity and solid content without damaging the system or causing inefficiencies.

4. Reducing Maintenance Costs:

Because pulp pumps are designed to handle tough, abrasive materials, they are generally built for durability. High-quality pulp pumps can last for extended periods with minimal maintenance, which reduces the cost of repairs and replacements. This durability ensures that paper mills can maintain smooth and continuous production with fewer unexpected costs.

5. Energy Efficiency:

Modern pulp pumps are designed to operate with maximum energy efficiency. These pumps are engineered to reduce energy consumption while still providing powerful flow rates, which is important for large-scale paper mills where energy costs can be significant. By utilizing advanced pump designs, manufacturers can optimize their operations and lower their environmental impact.

6. Adaptability to Different Types of Pulp:

Not all pulp is the same—different types of pulp (such as hardwood or softwood pulp) can have varying consistencies and levels of fiber content. Pulp pumps are versatile enough to handle a wide range of pulp types, making them suitable for use in a variety of paper manufacturing processes. This adaptability ensures that the pump system can meet the needs of different stages in the production process, from pulp preparation to final paper output.

7. Integration with Other Systems:

Pulp pumps are often integrated into larger systems that handle the entire paper production process. Whether it's a pulping system, a cleaning system, or a refining system, the pulp pump ensures that materials are transported efficiently between these different parts of the plant. Their integration with other machinery ensures that the paper mill operates as a well-oiled machine, reducing bottlenecks and downtime.

Types of Pulp Pumps

1. Centrifugal Pumps:

Centrifugal pulp pumps are the most common type used in paper mills. They operate by using a rotating impeller to create a centrifugal force that moves the pulp through the system. These pumps are ideal for handling large volumes of pulp slurry with moderate viscosity.

2. Progressive Cavity Pumps:

Progressive cavity pumps are used for applications requiring higher pressures and more precise control of the pulp flow. These pumps use a rotating screw-like mechanism to move pulp, making them ideal for situations where the pulp has a high solid content or needs to be transported over long distances.

3. Peristaltic Pumps:

Peristaltic pumps are used when handling particularly viscous or abrasive pulps. These pumps move the pulp through flexible tubes, using rollers to compress and force the material along the pipe. This design reduces the wear and tear on the pump itself and is ideal for pumping thick, slurry-like materials.

4. Diaphragm Pumps:

Diaphragm pumps use a flexible diaphragm to move pulp through the system. They are often used in applications where consistency and precision are critical. These pumps can handle thick, slurry-like materials and are resistant to damage from abrasive particles.

Key Considerations When Selecting a Pulp Pump

1. Pump Capacity:

The capacity of the pump is one of the most important factors to consider. Depending on the scale of your operation, you may need a pump with a higher flow rate to meet the demands of a large paper mill. Understanding the volume of pulp that needs to be transported will help determine the right size and type of pump.

2. Viscosity of the Pulp:

Different types of pulp have different viscosities. A pulp with a higher viscosity will require a more powerful pump that can handle thick materials without clogging. Be sure to select a pump that is designed for the specific consistency of your pulp.

3. Material Durability:

Given that pulp contains abrasive particles, the material used for the pump components must be durable enough to withstand wear and tear. Pumps made of stainless steel or rubber-lined materials are often preferred for their ability to resist corrosion and abrasion.

4. Energy Efficiency:

Look for pumps that are designed with energy efficiency in mind. As energy costs continue to rise, selecting an energy-efficient pump can help reduce operational costs and improve the sustainability of the paper production process.

5. Maintenance Requirements:

Regular maintenance is essential to keep pulp pumps running smoothly. When selecting a pump, consider the maintenance requirements and how easy it is to repair or replace worn-out parts. Opting for a pump with longer service intervals and easily replaceable parts can reduce downtime and lower maintenance costs.

Conclusion: The Backbone of Paper Production

In conclusion, pulp pumps are an essential part of the paper production process. They ensure the efficient transport of pulp slurry, reduce operational costs, and improve the overall quality of the paper produced. By selecting the right type of pulp pump and maintaining it properly, paper mills can enhance productivity, minimize downtime, and stay competitive in a fast-evolving industry. Whether it’s for large-scale pulp transportation or handling specialized pulp types, investing in high-quality pulp pumps is a smart decision for any paper manufacturer.